03 Feb How to Choose the Right Rock Wool Insulation for Pipes, Buildings, and Industrial Equipment

Selecting the right insulation is a critical decision for industrial facilities and building projects where energy efficiency, fire safety, and long-term durability are essential. Rock wool insulation has emerged as one of the most trusted insulation materials across India due to its ability to perform reliably under high temperatures, reduce noise, and provide excellent fire resistance.

However, rock wool insulation is available in multiple forms, densities, and specifications. Choosing the correct product for a specific application plays a major role in achieving optimal performance, safety, and operational efficiency. This guide explains how to choose the right rock wool insulation for pipes, buildings, and industrial equipment, based on practical site requirements and operating conditions.

What Is Rock Wool Insulation?

Rock wool insulation is manufactured from natural volcanic rocks that are melted at extremely high temperatures and spun into fine fibres. These fibres are bonded together to form insulation products with excellent:

- Thermal insulation properties

- Acoustic (sound-absorbing) performance

- Fire resistance and non-combustibility

- Mechanical strength and durability

Depending on the application, rock wool insulation is produced in different formats to meet specific installation and performance needs.

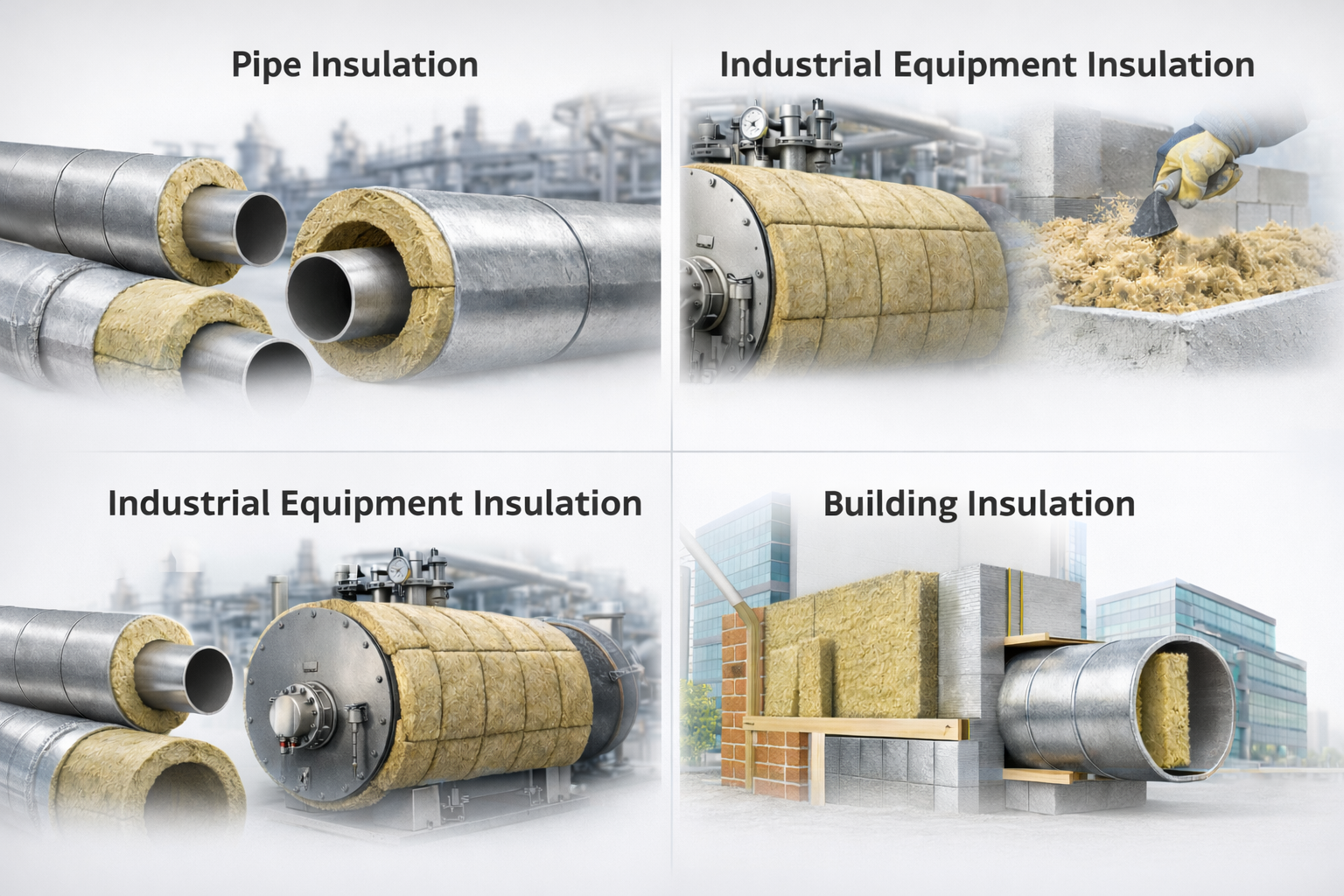

Types of Rock Wool Insulation and Their Applications

Rock Wool Insulation for Pipes

For piping systems, pre-formed rock wool pipe sections are commonly used. These are engineered to fit precisely around pipes, ensuring consistent insulation thickness throughout the system.

Typical applications include:

- Steam pipelines

- Hot water lines

- Chilled water systems

- Process piping in industrial plants

Key benefits of pipe insulation:

- Reduces heat loss and energy consumption

- Controls surface temperature for personnel safety

- Prevents condensation in cold systems

- Improves overall system efficiency

Pipe insulation is widely used in power plants, refineries, chemical plants, and other heavy industrial facilities.

Rock Wool Insulation for Industrial Equipment

For industrial equipment such as boilers, furnaces, vessels, reactors, tanks, and ducts, rock wool slabs or light resin-bonded mattresses are typically preferred.

Why these formats are used:

- High thermal resistance for continuous high-temperature operation

- Structural stability under mechanical stress

- Suitable for large flat or curved surfaces

- Long service life with minimal degradation

These insulation products are ideal for equipment that operates under demanding thermal and environmental conditions.

Rock Wool Insulation for Buildings and Construction

In building and construction applications, rock wool building rolls and slabs are widely used for:

- External and internal walls

- Roof and ceiling insulation

- HVAC ducts and shafts

Advantages in buildings include:

- Improved indoor thermal comfort

- Effective noise reduction between spaces

- Enhanced fire safety in commercial and residential buildings

- Ease of installation over large surface areas

Flexible insulation formats are especially useful where quick installation and full surface coverage are required.

Loose Rock Wool Insulation

Loose rock wool insulation is used in specialized scenarios, such as:

- Irregular or complex shapes

- Cavity wall insulation

- Areas where standard slabs or rolls cannot be installed easily

This format is typically applied in niche industrial or construction applications.

Key Factors to Consider When Choosing Rock Wool Insulation

Operating Temperature

The first and most important factor is the operating temperature of the system.

- Industrial piping and equipment often operate at high temperatures

- Insulation must maintain performance without melting or degrading

- Selecting insulation rated for the correct temperature range ensures safety and reliability

Density and Thickness

Density and thickness directly affect insulation performance.

General guidelines:

- High-density rock wool:

- Used in industrial applications

- Provides better mechanical strength and fire resistance

- Lower-density rock wool:

- Suitable for building insulation

- Offers flexibility and ease of installation

Proper insulation thickness is essential to:

- Achieve required thermal performance

- Meet design and safety standards

- Minimize long-term energy losses

Moisture Exposure and Environmental Conditions

Moisture exposure is a critical consideration, especially for outdoor installations or humid environments.

Important considerations include:

- Use of appropriate facings or protective cladding

- Prevention of moisture absorption

- Reduction of corrosion under insulation (CUI) risk

This is particularly important in industrial plants where equipment reliability and uptime are crucial.

Fire Safety Requirements

Fire safety should always be a priority when selecting insulation materials.

Rock wool insulation is:

- Non-combustible

- Does not contribute to fire spread

- Suitable for fire-critical applications

Choosing products that comply with relevant Indian and international fire safety standards provides added assurance for safety-sensitive projects.

Common Mistakes to Avoid When Selecting Rock Wool Insulation

Some common insulation selection mistakes include:

- Choosing insulation based only on initial cost

- Using incorrect insulation thickness

- Ignoring operating temperature limits

- Overlooking proper installation and protection methods

These issues can lead to:

- Higher energy losses

- Reduced insulation lifespan

- Increased maintenance and operating costs

Conclusion: Making the Right Choice

Rock wool insulation is a reliable and proven solution for both industrial and building applications when selected correctly. Its combination of thermal efficiency, fire resistance, acoustic performance, and durability makes it suitable for demanding environments across multiple industries.

By choosing the right rock wool insulation for pipes, buildings, and industrial equipment, projects can achieve:

- Improved energy efficiency

- Enhanced safety and fire protection

- Long-term performance and cost savings

Working with experienced manufacturers and suppliers ensures that insulation products are selected to meet specific application requirements and deliver consistent results throughout their service life.

No Comments